Home

-

THE WALNUT CREEK PLANING STANDARD

At WCP we strive in our lives and business to treat the people we meet and do business with as we would hope to be treated. It is our standard to set and exceed our customers expectations each and every day. We hope to achieve this goal on every order and expect to hear from our customers if we do not meet the expectations we have agreed to. -

WHAT WE DO

We manufacture high quality hardwood components and finished hardwood goods for many industries including the door industry, the stair industry, furniture industry, butcher block industry and many others. -

FACILITIES

We operate a 125,000 sq ft of manufacturing facility for our wood components and finished wood products and a separate facility of 10 acres with our air drying and kiln drying facility. We have the capability of drying up to 300,000 bd ft of material at any one time in our state of the art kiln drying facility. These 2 facilities allow us to control our products from the forest to final product giving a quality and level of craftsmanship in our products unmatched in the industry. -

PRODUCTS

We manufacture a wide array of standard and custom components. Each piece is careful inspected by our fine craftsmen to ensure you receive the exactly what you ordered. From moulder blanks to the finished box newel; we have the ability to make any hardwood component you might need.

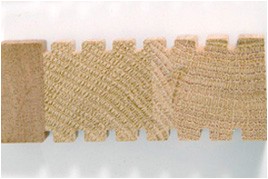

See our latest new product Enviro-Brick compressed hardwood fireplace fuel at ENVIROBRICK.net. Enviro-Brick is an environmentally friendly recycled hardwood fireplace fuel that burns longer than ordinary cordwood but uses ½ the storage space without the mess of typical firewood.